Advanced Sugarcane Bagasse Pulp Coating Production Line for Eco-Friendly Molding Solutions

Détails sur le produit:

| Lieu d'origine: | CHINE |

| Nom de marque: | Osmanuv |

| Certification: | ISO9001 |

| Numéro de modèle: | OSM-XT-1024 |

| Documents: | PULP MOLDING AUTOMATIC SPIN...NE.pdf |

Conditions de paiement et expédition:

| Quantité de commande min: | 1 set |

|---|---|

| Prix: | Négociable |

| Détails d'emballage: | Boîte en bois |

| Délai de livraison: | 45 jours |

| Conditions de paiement: | T / t |

| Capacité d'approvisionnement: | Négociation |

|

Détail Infomation |

|||

| Efficacité du revêtement: | Grande efficacité | Condition: | Je vous en prie. |

|---|---|---|---|

| Salle de pulvérisation: | 304 en acier inoxydable | Emballer: | Casse en bois |

| Peinture à l'utilisation de la peinture.: | 100% | Type de lampe: | Type de fibre de carbone |

| Nom de machine: | Machines à revêtement par rotation | Emballage: | Case en bois standard |

| Mettre en évidence: | sugarcane bagasse pulp coating line,eco-friendly pulp molding machine,pulp molding coating production line |

||

Description de produit

Advanced Sugarcane Bagasse Pulp Coating Production Line for Eco-Friendly Molding Solutions

Composition of Production Line:

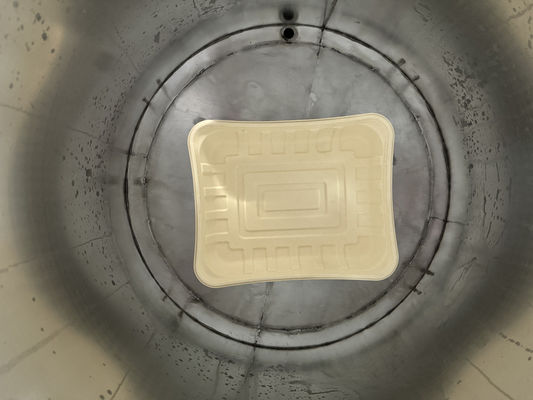

This versatile production line utilizes sugarcane bagasse pulp, combining cutting-edge spraying and coating technologies. Designed to improve the strength and appearance of molded pulp products, the system enhances both performance and aesthetic quality.

Product Description:

This advanced coating line enables the creation of coated pulp products using renewable sugarcane bagasse. The spray coating system ensures a consistent, high-quality finish with a focus on sustainable manufacturing practices.

Technical Parameters:

| Parameter | Specification |

|---|---|

| Material Used | Sugarcane Bagasse Pulp |

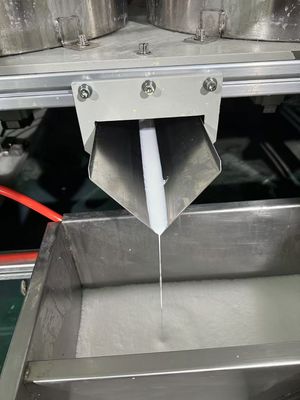

| Spray Coating Technology | Electrostatic Rotary Spray |

| Coating Material | Eco-friendly, Non-toxic Coatings |

| Production Output | 1000 - 3000 units/hour |

| Temperature Range | 30 - 60°C |

| System Control | Automated PLC Control with Touchscreen |

| Customizable Features | Yes, coating types and thickness |

Application:

-

Food Packaging: Safe, non-toxic coatings for food-grade packaging.

-

Cosmetic Packaging: Eco-friendly coatings for cosmetic containers.

-

Electronic Packaging: Sustainable packaging solutions for electronics.

Customization:

-

Adjustable coating viscosity for varying product types.

-

Tailored production capacity to suit factory needs.

-

Coating colors and textures can be customized.

Feature:

-

Automated cleaning cycle for low maintenance.

-

Compact and modular design for easy integration.

-

Suitable for high-throughput production without compromising quality.

-

Eco-friendly operation, aligned with sustainable manufacturing goals.

Support and Services:

-

Post-Sales Support: Lifetime technical support and spare parts availability.

-

Custom Engineering: Tailored engineering solutions for unique requirements.

-

Installation & Commissioning: On-site support for installation.

Packing and Shipping:

-

Packaging: High-quality packaging to prevent shipping damage.

-

Shipping: Global delivery with flexible shipping options.

FAQ:

-

How does the coating process enhance the pulp product?

-

The coating improves the durability, resistance to water, and appearance of the pulp product.

-

-

What types of coatings can be applied to the products?

-

The system can apply various eco-friendly coatings, such as water-based and UV coatings.

-

-

Can the production line handle large-scale manufacturing?

-

Yes, it is designed for both small and large-scale production environments.

-